By Pat Pine, RDH

I was asked to perform an informal case study on dental office evacuation valves. This was a challenge in many ways. Several offices I contacted were leery to allow swab testing in their offices even though they said they felt confident of their disinfection process.

My infection control flag went up many times in those practices. If they felt confident, why are they leery of doing a simple swab test? What was the risk to them? One office wanted to check with his lawyer, wanted my license number, and much more seemingly ridiculous information. The offices that were welcoming wanted to know how they could improve their infection prevention protocol. A big benefit was they received bags of disposable valves for allowing testing of their disinfected valves.

Testing was done to determine if the valves were contaminated even after disinfection. What are the consequences of the unknown invisible organic matter? What pathogens are nesting here? When disinfected, what pathogens are being reduced or present?

As an experienced infection prevention and safety specialist, I performed the swab-testing. After reviewing the results, I was glad I had donned the appropriate PPE. Maybe I should have worn a hazmat suit!

The Down and Dirty Results

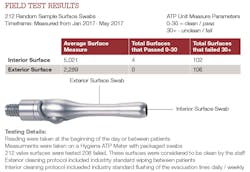

I processed 212 valve surfaces and determined they were, yes, contaminated after a routine disinfecting protocol. Discovering the bacterial load on dental unit vacuum valves left me with an uneasy feeling. Are we creating a healthy environment for our patients? Occupational Safety, Asepsis and Prevention (OSAP) has repeatedly stated that dental patients should be in a safe dental environment, which includes the entire dental facility and all the processes.

Just to begin to discover where problems happen, the first question should be if the valves were disinfected according to manufacturer’s instructions? Metal valve companies recommend routine disassembly, scrubbing, and reprocessing of the surfaces between patients. Minimal industry standard between patient protocol should be to:

- Wipe once to clean

- Wipe a second time to disinfect

Backflow Risks

It’s not new information that backflow from low-volume saliva ejectors is happening. Research has shown that when a patient seals their lips around the tip of the salvia ejector, backflow can occur via the pressure created in the patient’s mouth. Studies report that gravity pulls fluid back toward patient’s mouth when tube positioning is above the patient’s mouth or when both high or low suction is used at the same time. Unfortunately—like not going into the water for 30 minutes after eating myth—we have taught our patients to close their lips around the saliva ejector.

The CDC recommends that the dental community advise their patients not to close their lips around the saliva ejector. CDC concluded that research confirms the significant risk in backflow with microbial cross contamination between patients.

Is your office using old, outdated operating procedures that are as myth based as watermelon seeds germinating in your stomach? Updated written policies and procedures are a must for any dental setting. Standard operating procedures (SOP) can be used for training and OSHA safety purposes. These policies should be reviewed on an annual basis. Checklists are powerful. For reminders of what might be forgotten in daily routines, go to oshatrainingbootcamp.com to find checklists and more.

Replacing the Old

Replacing an old car with a new car increases safety with airbags, hands-free phone connection, and cameras in the rear panel to prevent hitting a child or running over a bicycle. The prevention is worth every penny. Valves are now available to keep patients safe in any dental facility. New disposable versions are clean and offer backflow prevention. We need to protect our patients from microbial biohazardous debris and possible transmission of disease via backflow. The Hippocratic Oath and professional ethical standards demand that we first do no harm.

Editor’s Note: This article’s preparation was supported by Dove Dental, Inc.

Patricia Pine, RDH, COM, is a national and international speaker on topics including Occupational Safety and Health Administration (OSHA) safety, infection prevention, and orofacial myology. She conducts in-office OSHA boot camps and seminars for the dental community, and she is a member of the Organization for Safety, Asepsis and Prevention (OSAP) speaker’s consultant bureau. She can be reached at [email protected] or OSHAtrainingbootcamp.com.